ROUND LINK MINING CHAINS

Over 110 year experience allowed FASING to achieve the highest quality of round link mining chains. The detailed control that is performed at every stage of the production process, the use of highly optimized steel and the wide range of chain grades allows FASING to offer, pursuant to the company’s motto, the chain that is perfectly suited for the specific conditions of its performance.

The quality of FASING mining chains is proved with recognition and customer satisfaction around the world.

Round link mining chains

acc. to DIN 22252, PN-G-46701 and FASING Technical Requirements

Application

Armoured Face Conveyors, Beam Stage Loaders, road header machines, coal plows, other equipment that requires this type of chain.

Product manufacturing

acc. to DIN 22252 or PN-G-46701 or GB/T-12718 or GOST 25996 standard

Notice! All anti-corrosive coatings decrease the chain mechanical properties, therefore, the application of any anticorrosion protection needs individual agreement with a customer when issuing purchase order.

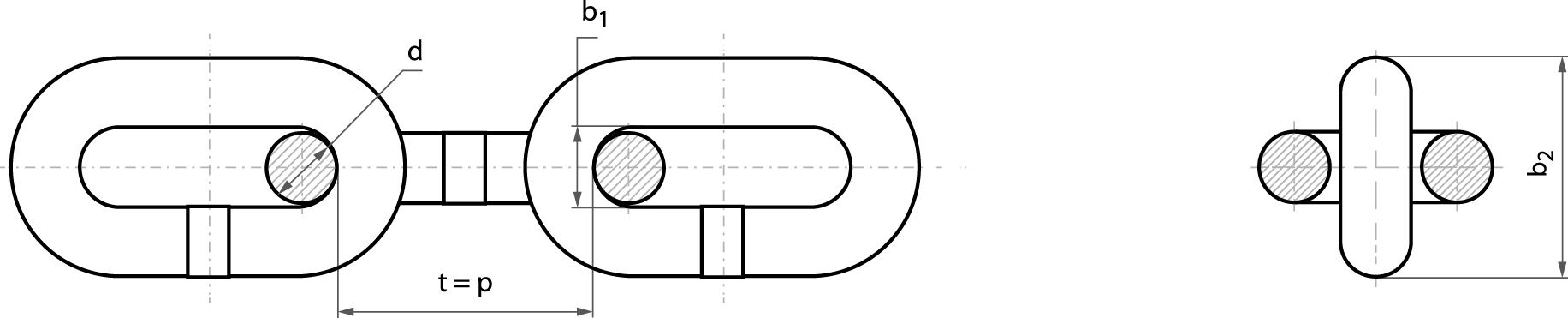

Dimensions

Link chains of increased properties

Grades PW-9, C-SUPER, D-3, D-3 EXTRA, E-FASING

Chains of increased grade properties: PW-9 (>900MPa), C-SUPER (>900MPa), D-3 (>1000MPa), D-3 EXTRA (>1050 MPa), E-FASING (>1100 MPa) are characterized by much higher performance parameters in comparison to chains mentioned in PN and DIN standards. The increased durability and operation strength of the chains is a result of introducing the highest quality steel to the production process. The applied steel is nonstandard, highly optimized –WO (W-highly, O-optimized), conforming to DIN 17115, PN - 92/H - 93028 standards, with alloy micro-additions acc. to FASING Technical Specifications. The WO steel and special, multiple, heat treatment guarantee achieving higher, more favourable, actual technical and performance parameters in chains. This technology provides an optimal, repetitive, hardness distribution in every link, moreover, in the case of PW-9, D-3, D-3 EXTRA, E-FASING grades it allows to obtain diverse hardness in one single link, i.e. hard crowns and plasticized legs of lower hardness. It is not recommended to use chains of increased properties, particularly the chains of the highest grade i.e. D-3 EXTRA and E-FASING in harsh, aggressive environment because of the risk posed by pitting corrosion and friction martensite that lead to operation failure.

In such cases, we suggest individual chain selection to specific performance conditions. Depending on the longwall degree of aggressiveness, we advise to use various types of protection applied onto the chain surface:

- preservation with special anticorrosive lubricant FAS-KBP 50/00/22,

- preservation with special anticorrosive oil,

- hot galvanizing FAS-Zn-O,

- metallization (inlet protection) FAS-Zn-M.

On the basis of DIN 22252 standard, mechanical properties of round link chains apply to natural, dry, black condition, which occurs after the technological production process. Pursuant to the standard, the chain strength parameters which include protective coatings are decreased ca. 10-20%. This percentage change must be considered when selecting the chain or making calculations. This phenomenon is known as the Rebinder effect.

.png)

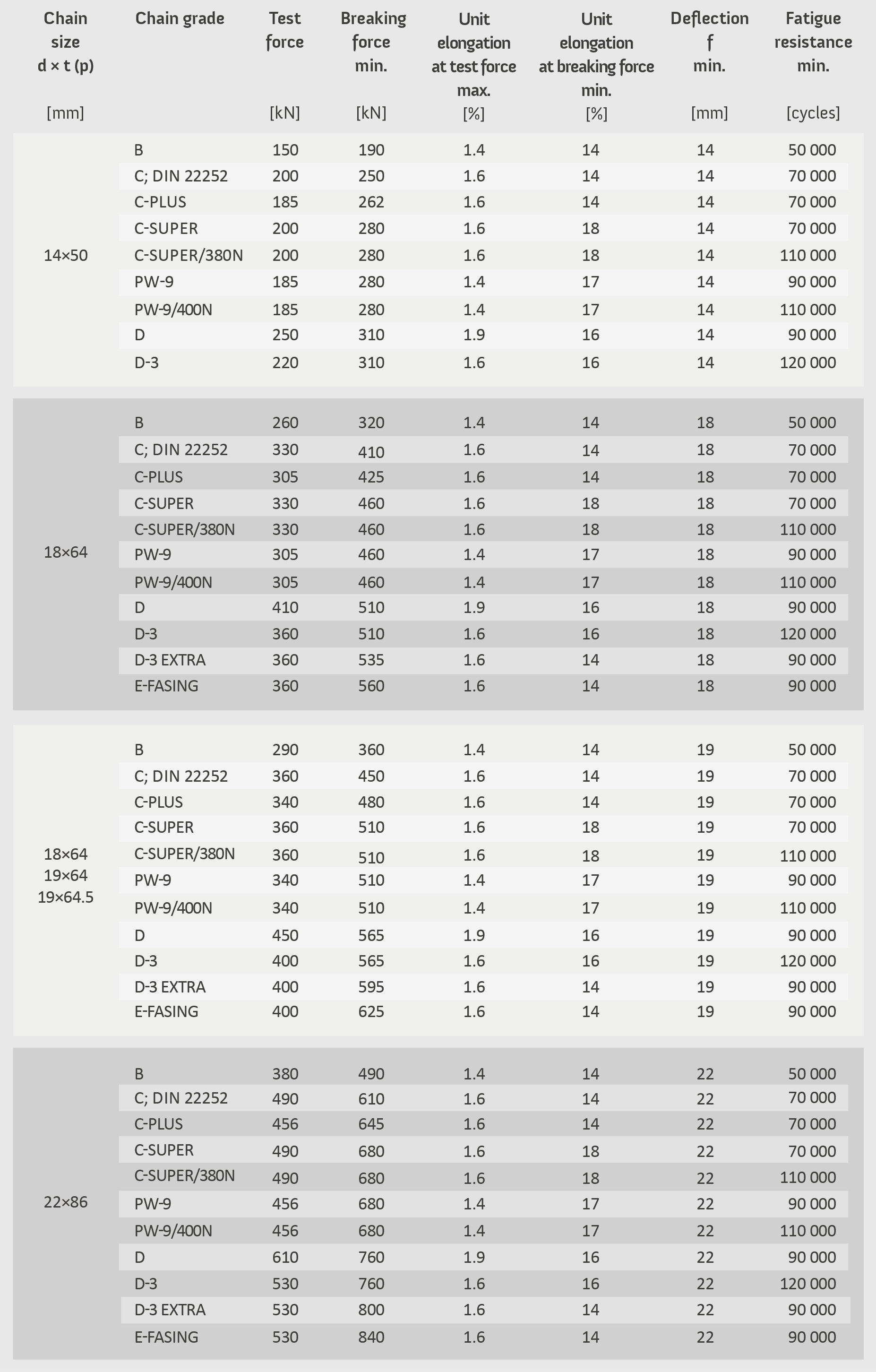

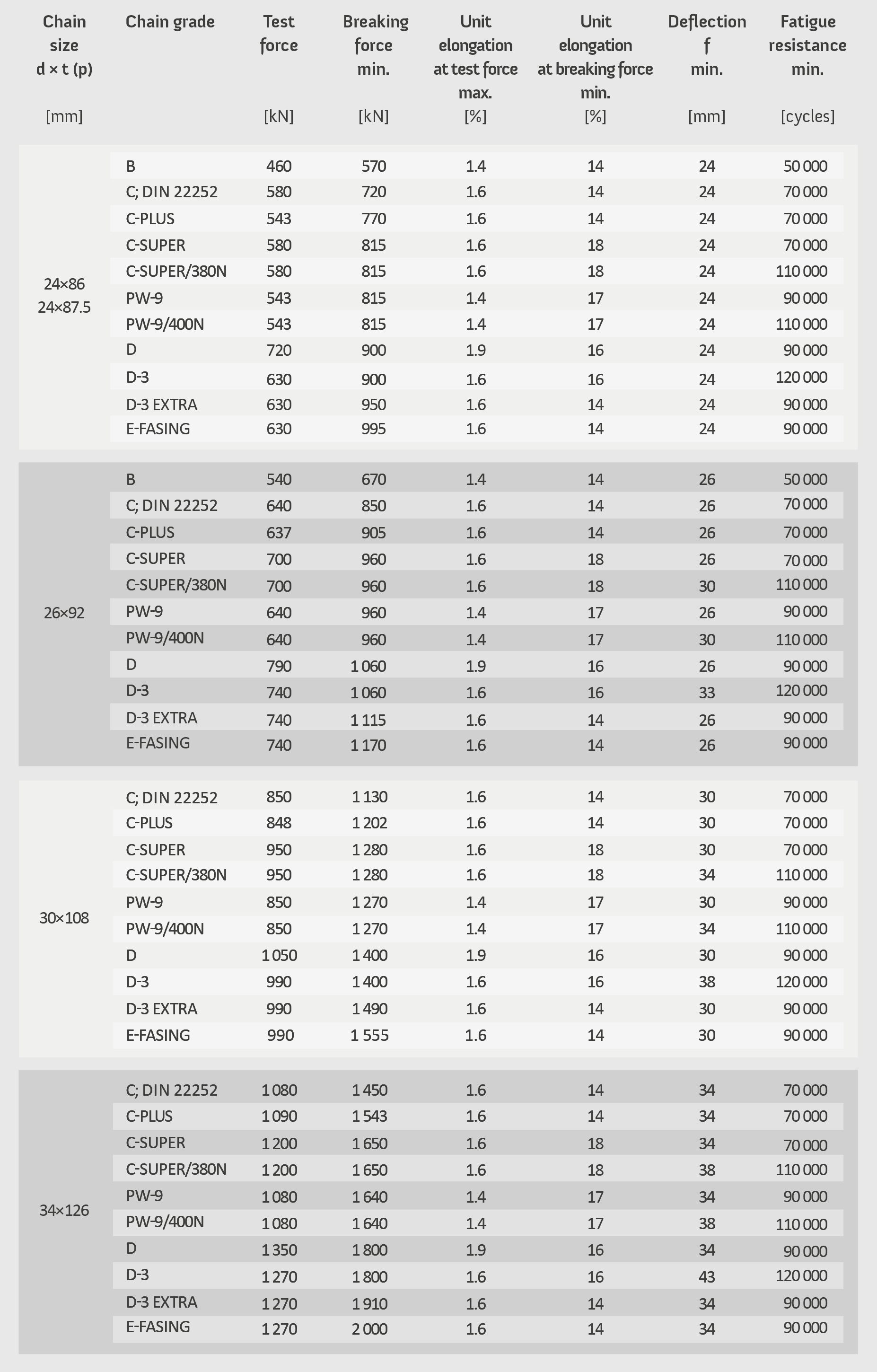

Mechanical properties

Parameters

Fatigue resistance T [cycles] and impact force KV [J] according to DIN 22252 standard and FASING Technical Requirements; in other cases to be agreed with FASING.