Chain assemblies

Chain assemblies with one, two, three and more chain strands of outboard and inboard chain guidance, including flight bars, clamps, locks, which have been made according to proper technical documentation and individual construction designs. The assemblies are used in mining conveyors, heating industry, agriculture, power industry, metallurgy and other branches of economy. The standard chain of increased strength parameters, resistant to abrasion and case hardened, may be used in all chain conveyors acc. to their technical design and customer request. Chain mechanical properties of the assemblies are presented on the applicable pages of this catalogue.

Twin inboard

chain assemblies

to chain conveyors for preparatory works (PRP-150)

The applied chain

• 18×64, 19×64, 19×64.5 grade C or PW-9; length from 80 m to 200 m, grade PW-9; length from 40 m to 200 m, grade FAS-UT, FAS-US or FAS-US EXTRA to short conveyors; length up to 40 m.

Product manufacturing

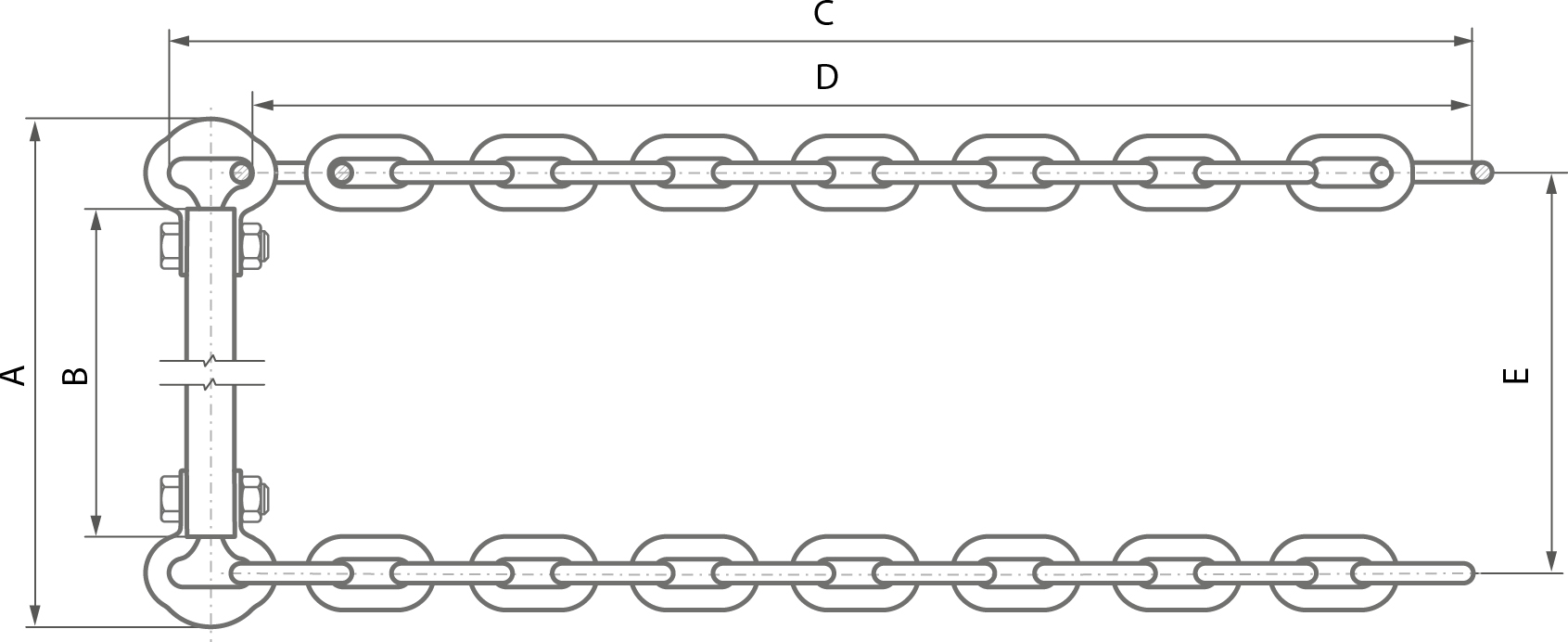

Twin inboard chain assemblies to chain conveyors for preparatory works (PRP-150) are primarily made in segments of 321 link length = 20 544 mm, by applying the following chains of specially selected parameters, lengths and tolerances: 18×64, 19×64, 19×64.5 acc. to DIN 22252, PN-G-46701 and wear resistant, forged flight bars and clamps which are assembled with selflocking nuts or according to other individual solutions.

Twin inboard

chain assemblies

to AM-50 Roadheader

The applied chain

• 18×64, 19×64, 19 x 64.5 grade FAS-UT, FAS-US and FAS-US EXTRA

Product manufacturing

Twin inboard chain assemblies for AFCs in AM-50 Roadheaders are primarily made in segments of 177 link length = 11 328 mm, by applying special hardened chains 18×64 grade FAS-UT, FAS-US, FAS-US EXTRA of higher wear resistance and respectively selected lengths and tolerances. Special, wear resistant, forged flight bars of strengthened, new construction are attached to chain assembly. The flight bars are optimally adjusted to a profile of the pan E-180; they are assembled to forged clamps with high quality bolts and self-locking nuts.

The chains are made of steel according to the requirements of DIN 17115 German standard and FASING specifications.

At the request of the customer, there is a possibility to apply double flat link chain 22×86-61 acc. to DIN 22255 and FASING Technical Requirements.

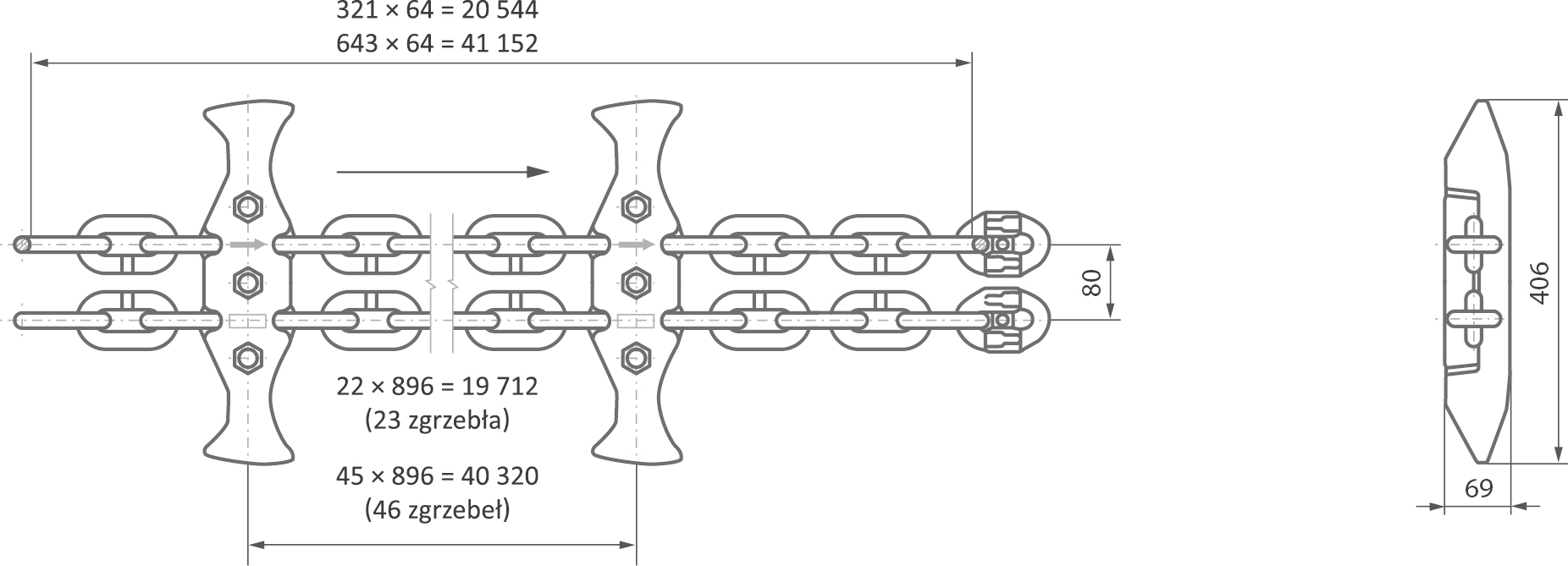

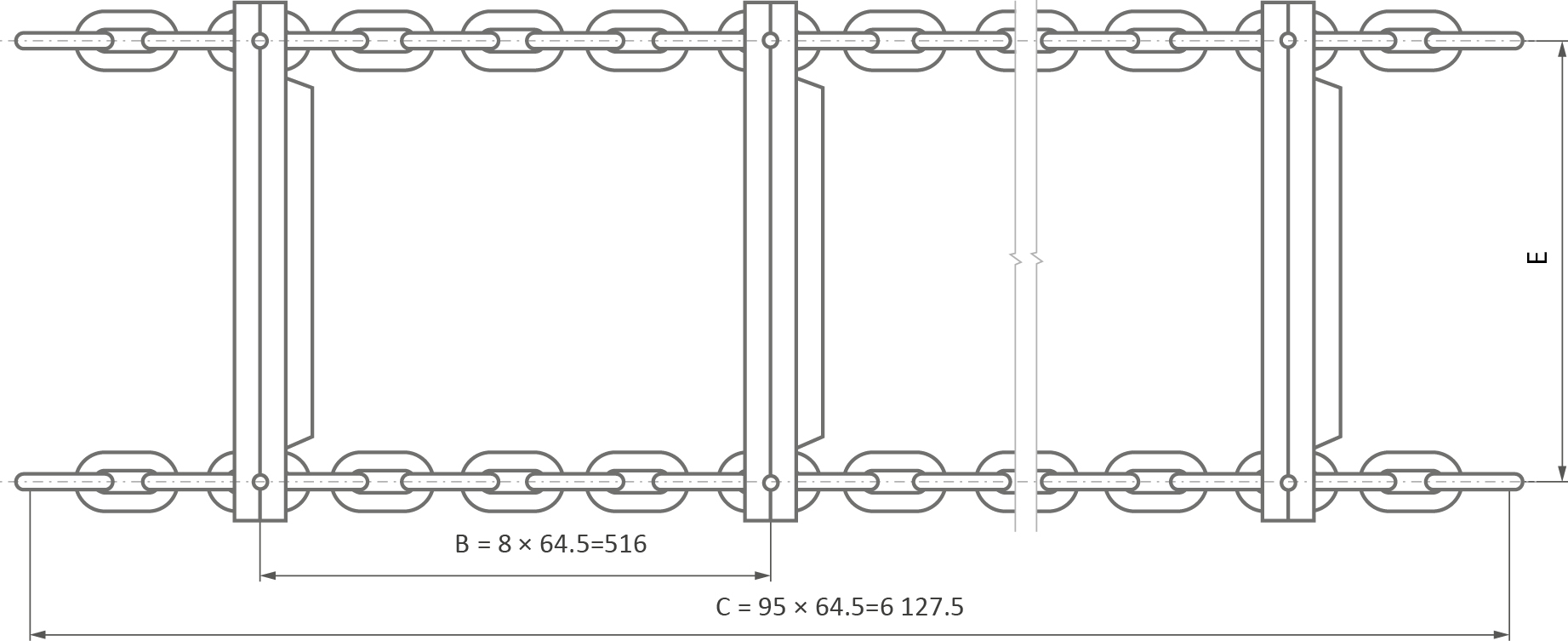

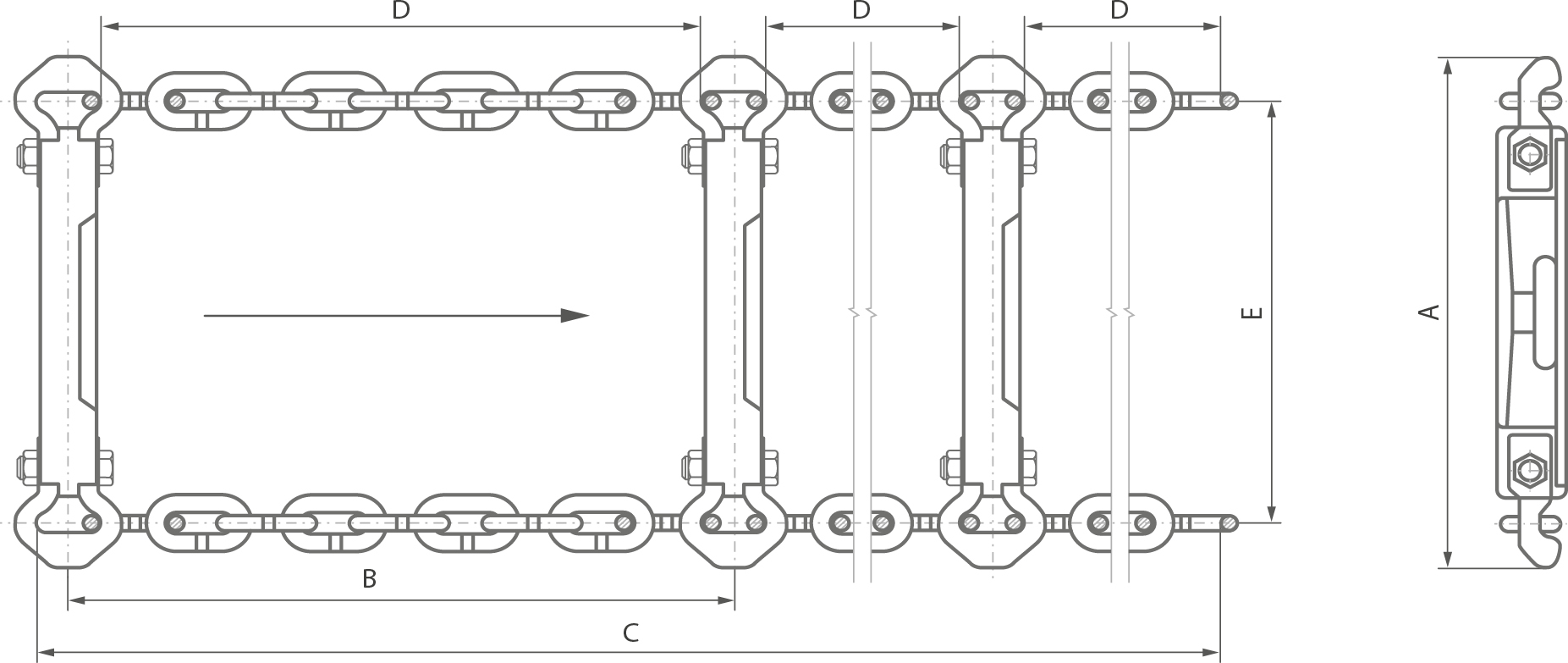

Twin outboard

chain assemblies

to chain conveyors installed in AM-65, AM-75, AM-85, AM-105 roadheaders.

The applied chain

• 18×64, 19×64, 19×64.5 grade FAS-UT, FAS-US or FAS-US EXTRA with non-lock scaper bars and scraper bars with locks

Product manufacturing

The complete twin outboard chain assemblies to AM-75 roadheaders are manufactured in segments of 95 link length = 6127.5 mm by applying exclusively selected chains 19×64.5 acc. to DIN 22252 German standard and wear resistant, assembled scraper bars. At the request of the customer, any length of paired chain strands is optional.

Non-lock chain assembly

Lock type chain assembly

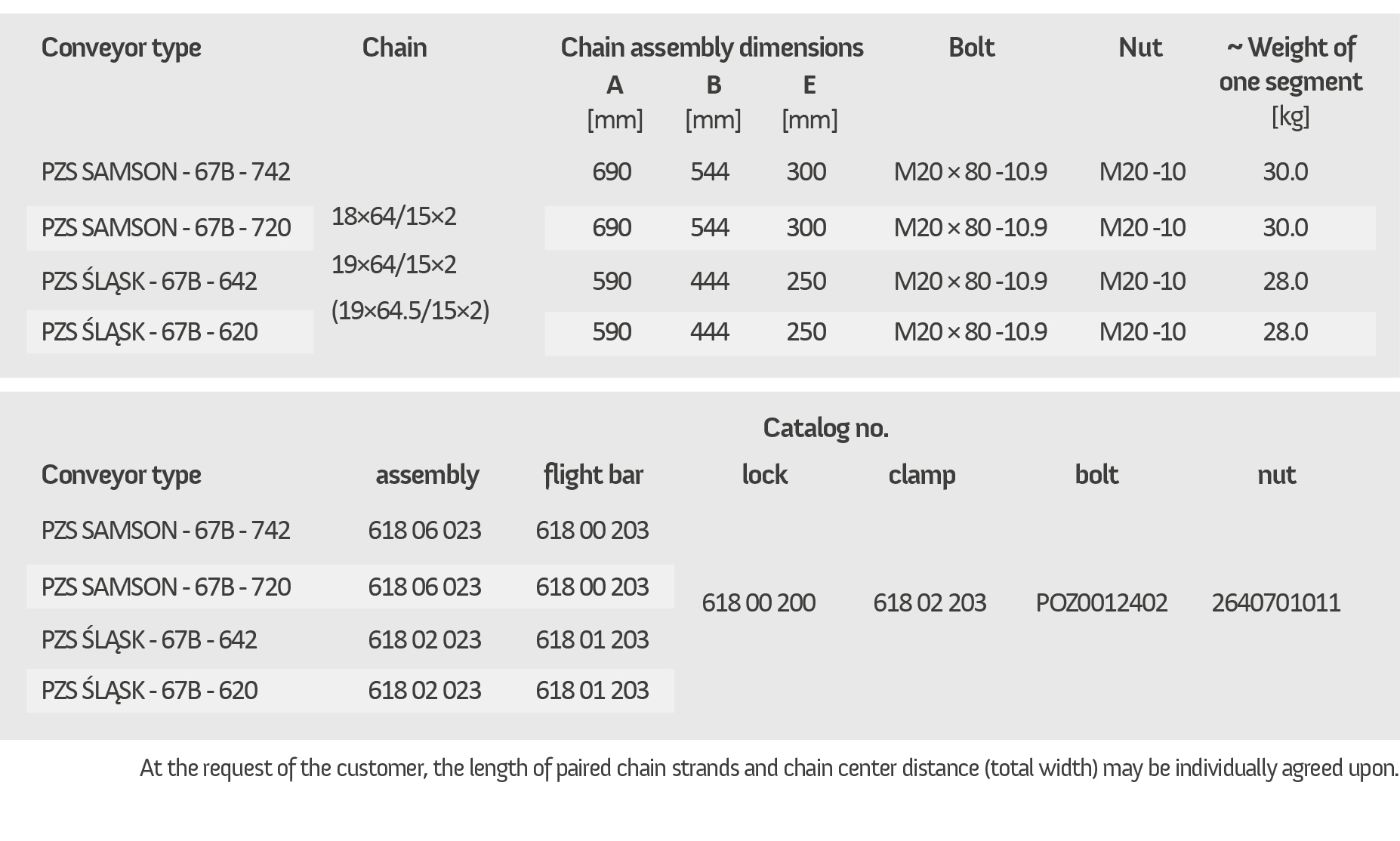

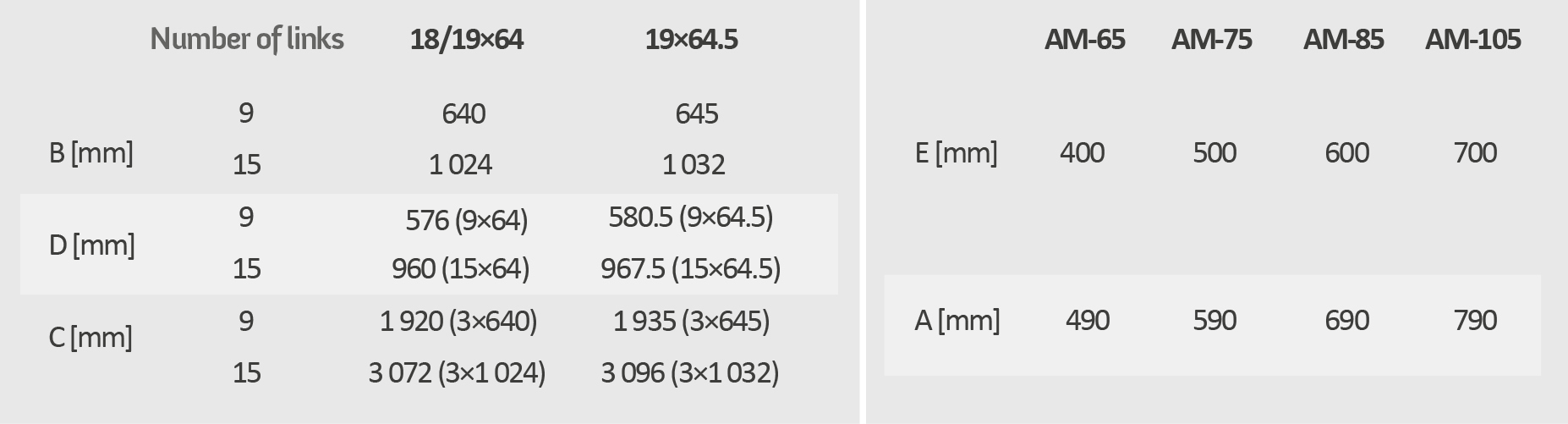

Twin outboard

chain assemblies

with complete scraper bars to de-ashers and other chain conveyors

Chain

• 24×86 grade FAS-UT, FAS-US or FAS-US EXTRA and others

Product manufacturing

Twin outboard chain assemblies to slag traps, used in fuel and energy sector, are generally manufactured in segments of 5 and 7 links of paired, specially hardened chain 24×86 grade FAS-UT or FAS-US. The assemblies comprise of wear resistant scraper bars and are mounted with locks 24×86, or they are assembled according to other individual designs.

Dimensions

E and A acc. to the customer’s specification.

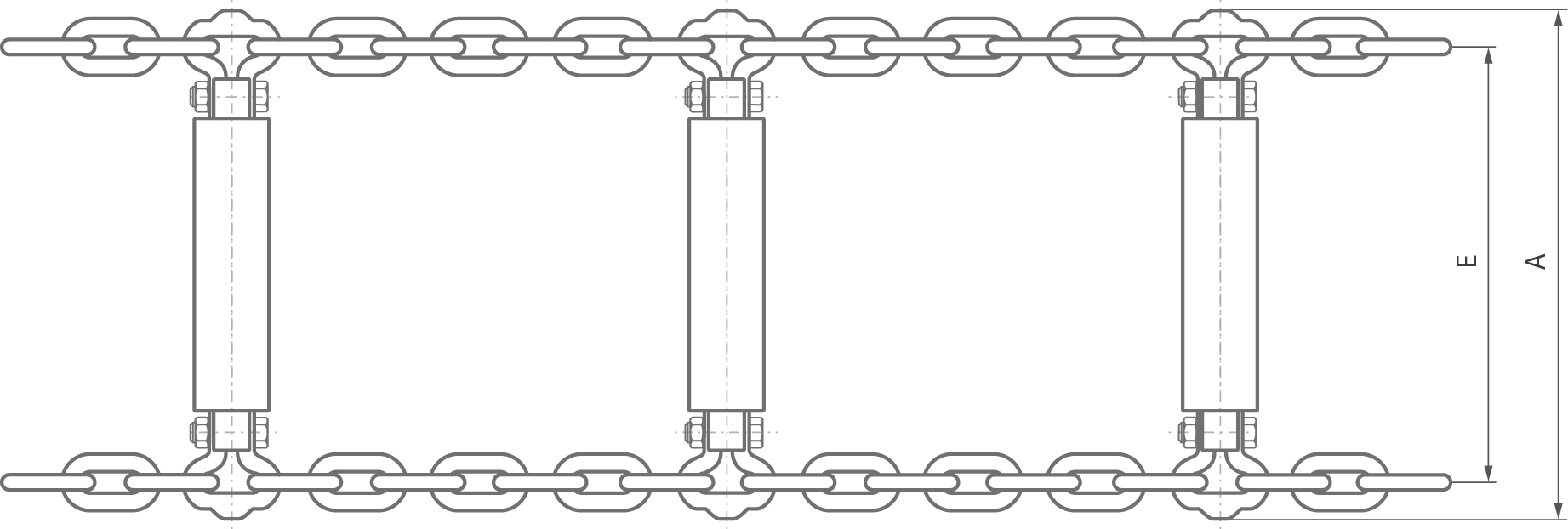

Twin outboard

chain assemblies

to shuttle cars

Chain

• 18×64; two seven-link chain strands of grade FAS-UT, FAS-US or FAS-US EXTRA with exclusively designed scraper bars or made according to individual construction

Dimensions

E and A acc. to the customer’s specification.

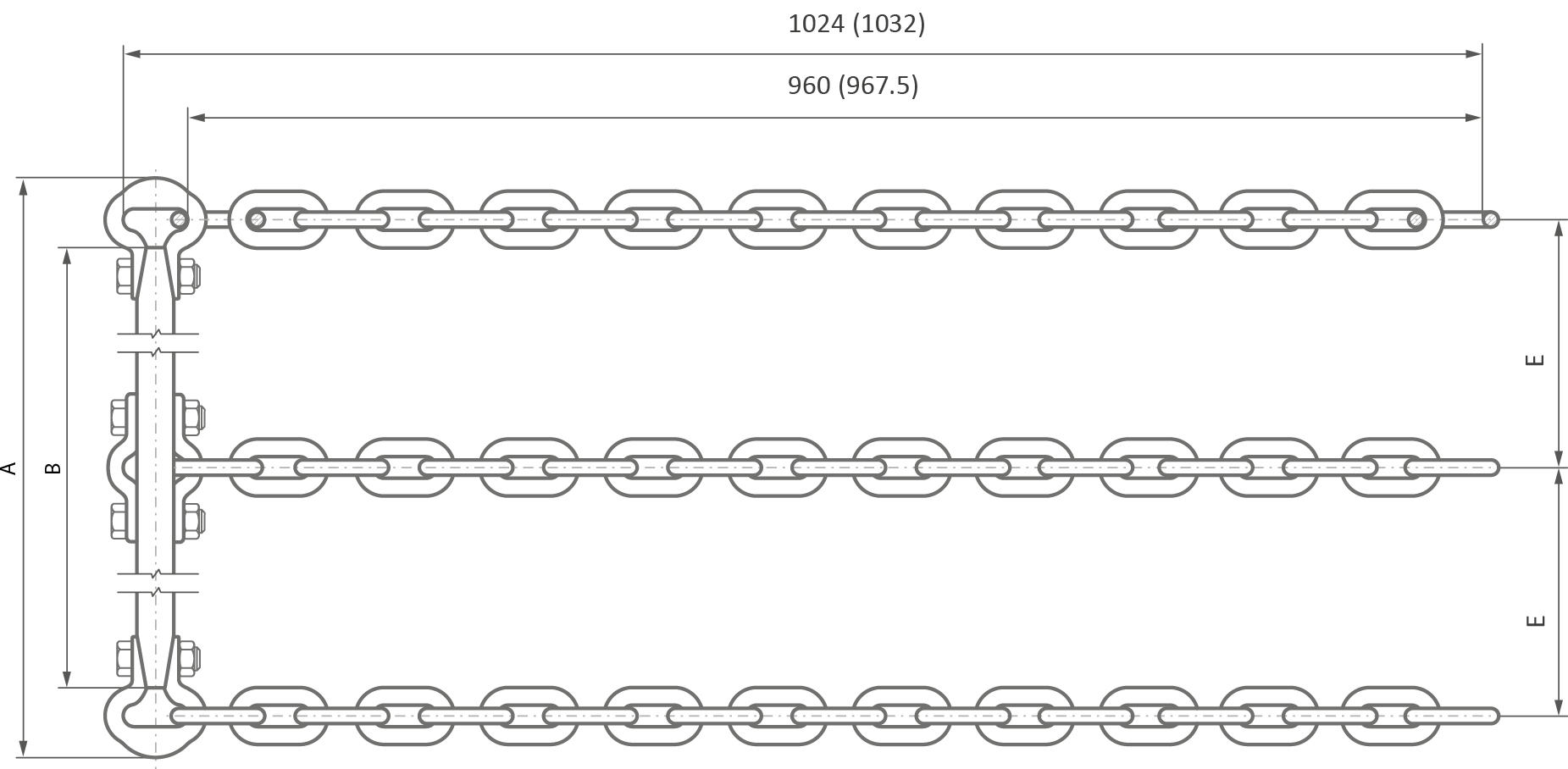

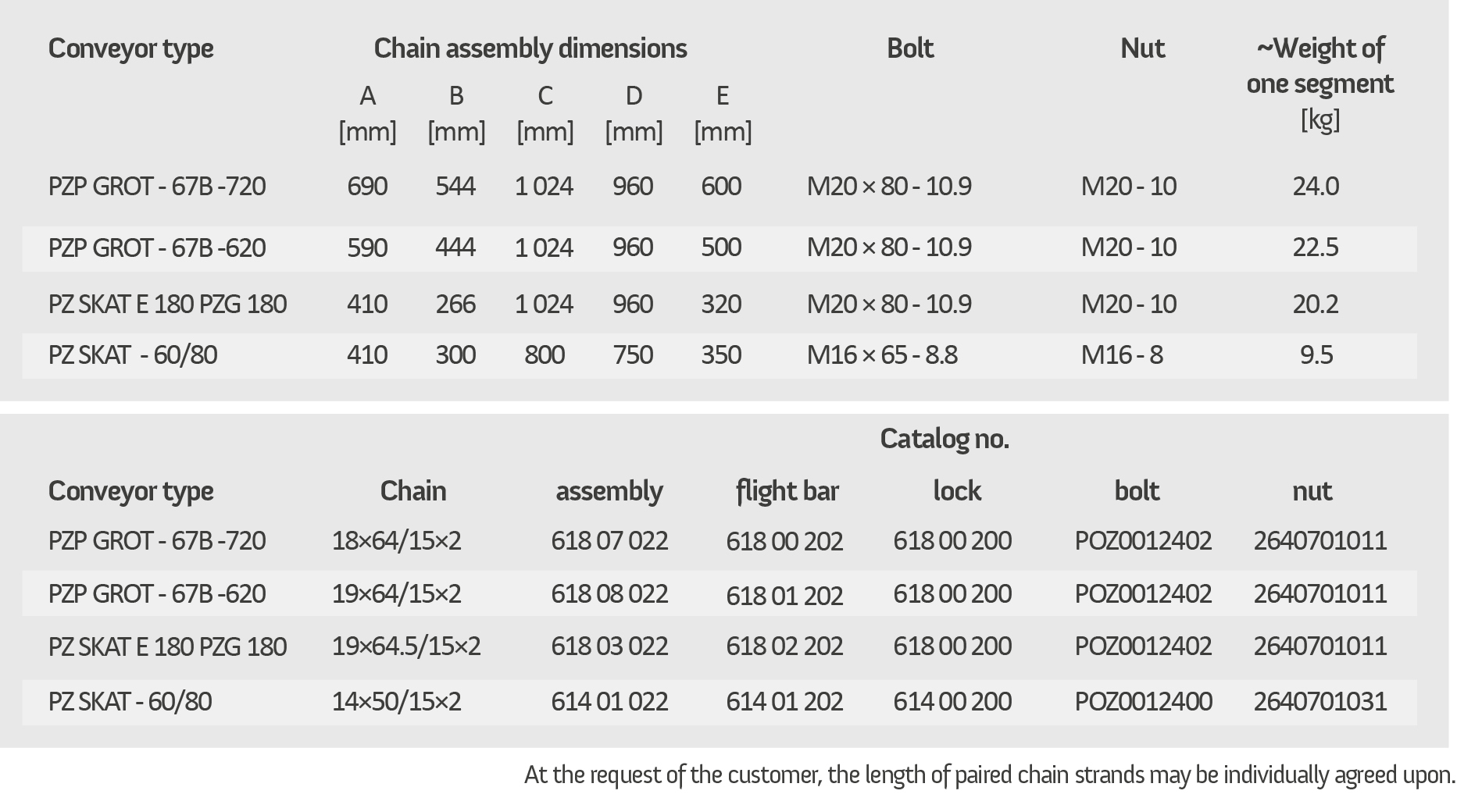

Twin outboard

chain assemblies

for PZP GROT, SKAT, ŚLĄSK, SAMSON flight bar conveyors

Lock type

Triple inboard chain assemblies